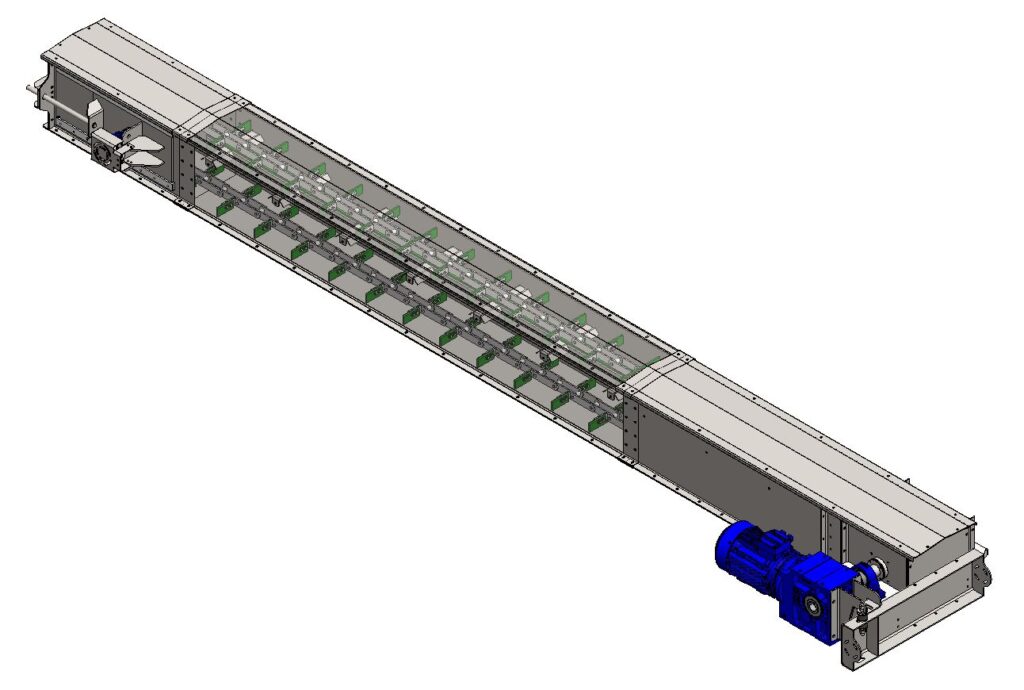

CHAIN CONVEYOR

FORDER Chain Conveyors,it works effectively both in horizontal position and up to 30° upwards and has low power consumption according to its capacity.

It works by dragging the chain wings along the conveyor floor and pushing the material at the bottom of the conveyor. The bottom layer of the moving material carries all the material standing on it with it. This creates less torque, works efficiently and has low power consumption according to its capacity.

Chain conveyors can be produced as standard up to 600 t/h capacity. Please contact us for higher capacities.

Chain conveyors can be used in all types of bulk goods that hold dust, are in the form of grains and small pieces (n<50mm) and are homogeneous mixtures. Bulk goods with a humidity level of 40% and a temperature of 500°C can also be conveyed. Bulk goods that flow very easily (such as coal dust, sugar, roasted coffee) create some difficulties during transmission. For this, special type chains developed with experience prevent this situation. Chain conveyors are successfully used in all branches of the industry working with bulk goods and sawdust.

Advantages of chain conveyors; Small footprint, smooth linear transmission, dust-free and hygienic transmission, safer against explosion compared to bucket elevators, high and full filling and no excess space transmission, transmission under inert gas, a transmission that does not require much service, the possibility of feeding and exiting the goods from many places at the same time, a good mixing opportunity for bulk goods given in a dosed manner, requiring one-eighth of the energy of a pneumatic facility that conveys the same amount.

Depending on the number of input and output points, it is necessary to distinguish between single-deck and double-deck chain conveyor systems.