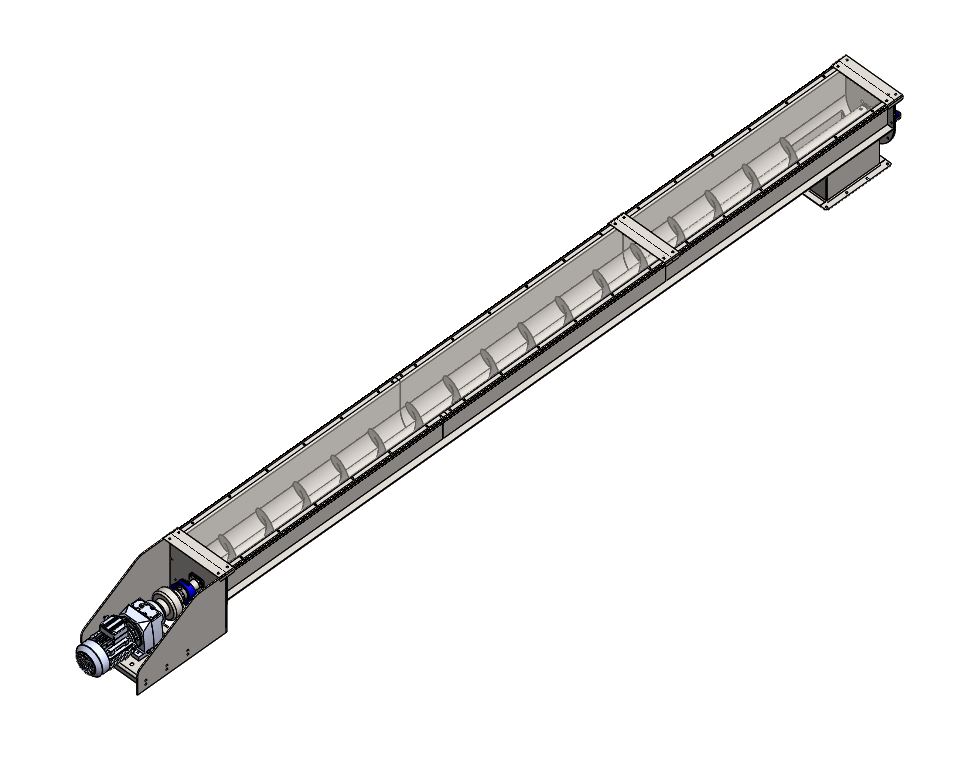

SCREW CONVEYOR

FORDER Screw Conveyors, it is used in different sectors for the purpose of feeding and transporting solid fluid materials.

According to the application area; Stainless, Hardox, special coated against wear and different spiral options suitable for the product are available.

One of the first mechanical transmission organs used in the transportation of bulk materials is the screw conveyor.

Some of the areas of use of screw conveyors can be listed as follows. Dust collection systems, products that need to be transported in accordance with food conditions such as flour, sugar, wheat, transfer of chemical materials, transportation of materials that need to be combined in certain proportions, systems that require dosing.

Advantages of screw conveyors; They can be manufactured in a modular structure, they can be easily assembled and disassembled, they have a compact structure, they can transfer high-temperature materials and low-abrasive materials.

Disadvantages of screw conveyors; They are not suitable for the transfer of sensitive, non-damaged and large-grained products, their transportation distances are not long, but it is possible to carry the product to long distances by transferring screw conveyors to each other, they cannot carry highly abrasive materials, their energy consumption is high compared to other transportation equipment and their carrying capacity is low.

Forder Tech manufactures different types of screw conveyors depending on the product to be carried. Some of these are; fixed pitch screw conveyors, variable pitch screw conveyors, increasing and decreasing pitch screw conveyors, conical shaft, shaftless screw conveyors, multi-trough screw conveyors, rubber leaf screw conveyors, cement screw conveyors, vertical screw conveyors, galvanized ice screw conveyors, stainless screw conveyors, pipe type ATEX screw conveyors.